PVC (Polyvinyl Chloride) leather is a popular and widely used material for clothing, footwear, accessories, furniture, and even automotive parts. The production process of PVC leather can either be calendar or casting, and each method has its own pros and cons. In this article, we will explore the differences between calendar PVC and casting PVC, and help you make an informed decision on which method to use based on your specific needs and budget.

Casting PVC

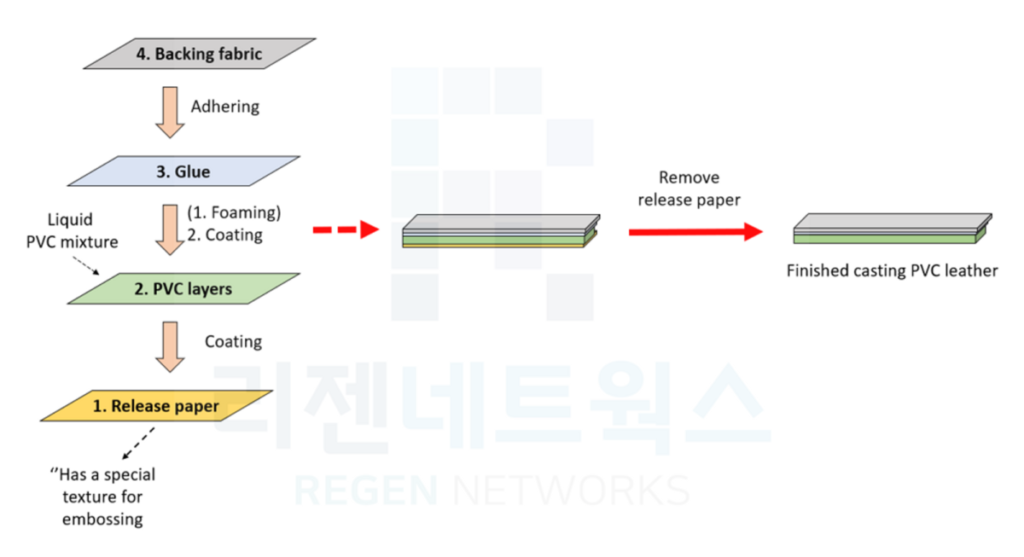

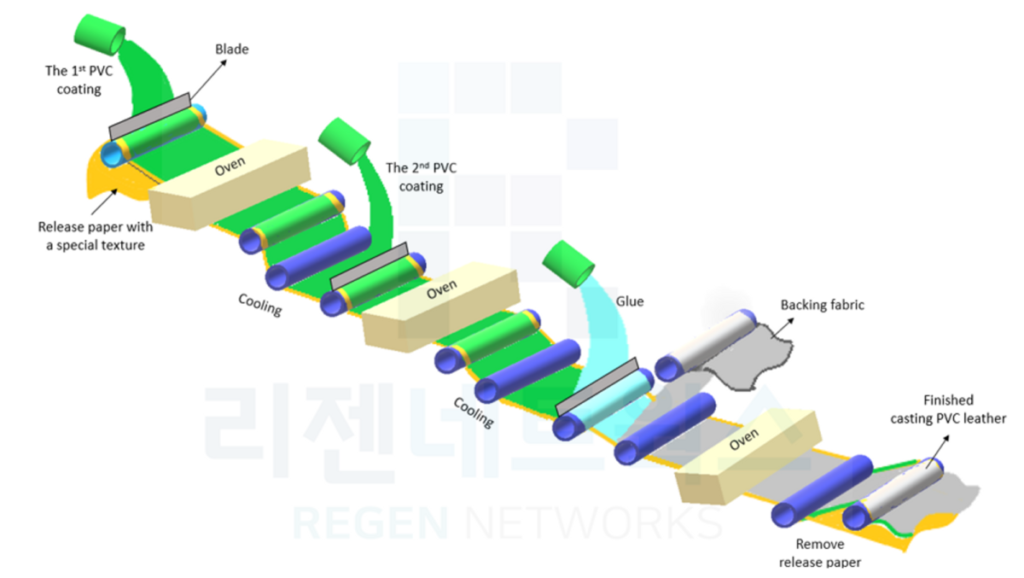

Casting PVC leather is produced by dissolving PVC powder with plasticizers, colorants, fillers, and other ingredients by using a solvent. The liquid mixture of PVC is then coated on the release paper (a special paper with texture). Then the following step is foaming, which means the released paper-PVC layers will go through the oven, where the thickening agent in PVC layers will be activated when expose to the heat, leading to the thicker PVC. Based on the desired thickness of finished products, sometimes the foaming step can be skipped and go to the next stage. The following stage is coating the glue to adhere PVC layers to the backing fabric. Finally, the manufacturer will remove the release paper and obtain the finished product with embossed patterns.

Calendar PVC

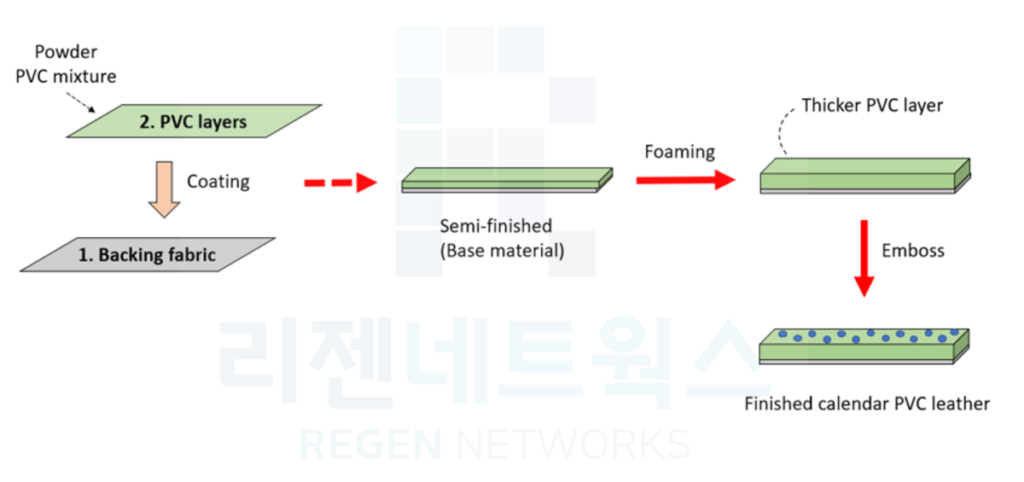

The calendar PVC production process starts by mixing PVC powder, plasticizers, colorants, and other ingredients in an extruder and then melting the mixture in a mixing mill. After that, PVC layers will be coated on a backing fabric, this structure it is called semi-finished (or base material). Then, it will go through a foaming machine to make the PVC layers thicker. Finally, the semi-finished will be embossed by using a roller with texture on it; result to the finished product will have a different texture on the surface.

Conclusion

In conclusion, the main difference between casting and calendar PVC is the material and the production process. Since the casting process uses many chemicals to dissolve the PVC powder, the finished artificial leather will have a softer hand feeling than the calendar one. In addition, casting PVC products are more expensive than calendar PVC due to the casting process having to use release paper, chemicals, and glue leading to higher production costs..

The comparison between casting and calendar PVC

| Property | Casting PVC | Calendar PVC |

|---|---|---|

| Material | PVC powder, additives, release paper, chemicals to dissolve, glue,… | PVC powder, additives, foaming powder, emboss rollers (steel, vacuum),… |

| Hand feeling | Softer | – |

| Patterns emboss | – | Deeper |

| Cost | Higher | – |

| Production line | One line | Many separate lines |

| Production efficiency | – | Higher |

Leave a Reply