PU synthetic leather, also known as polyurethane synthetic leather, is a popular alternative to genuine leather. It offers a versatile and cruelty-free option for various applications such as fashion, upholstery, automotive interiors, and accessories.

Structure of PU Leather

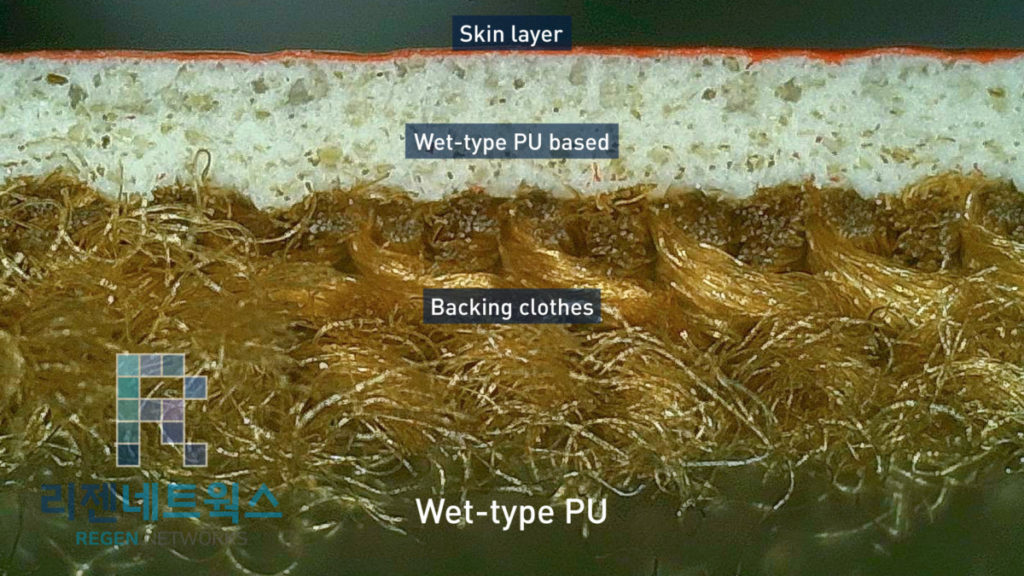

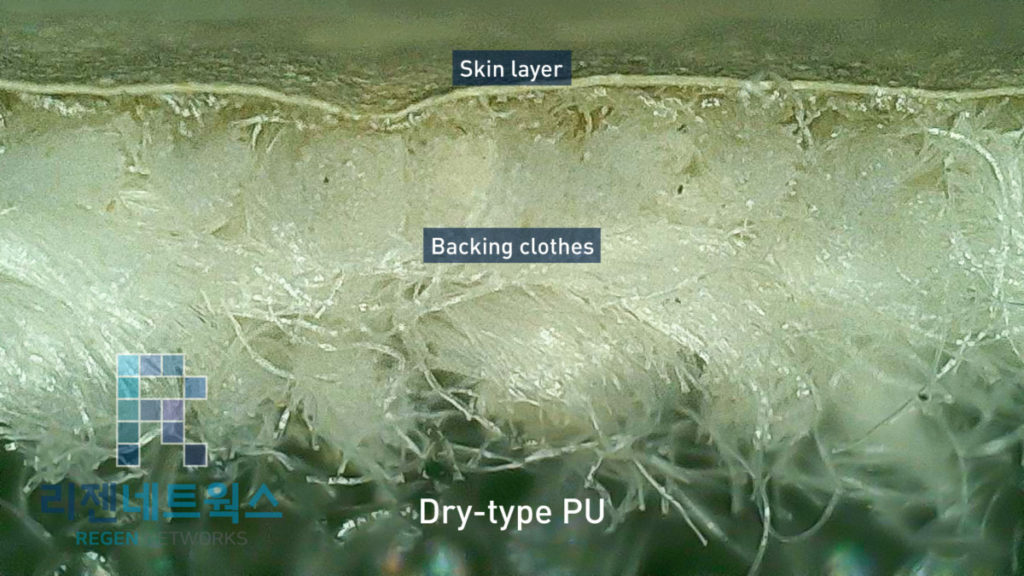

PU leather consists of three layers:

- Top Surface (Skin Layer): This layer can have a leather-like texture or a pattern according to customer preference.

- Foam Layer: Located between the top surface and the bottommost layer, this microporous cellular structure gives the material a foam-like texture. It enhances the texture and hand feel of the PU leather.

- Bottommost Layer (Backing or Substrate): Made of textile material, this layer provides support and stability to the PU leather.

PU leather can have two different structures:

- Skin + Backing

- Skin + Foam + Backing

The latter structure includes a foam layer, providing additional thickness and dimensional volume to the material.

Production of PU Synthetic Leather

The production process of coated PU leather involves the use of a liquid-form PU resin composed of polyurethane polymer chain particles. Traditionally, the solvent used was dimethylformamide (DMF), an organic and toxic solvent. However, newer water-based technology has been introduced.

In the water-based process, the PU particles disperse in water as an emulsion instead of being dissolved in DMF. This type of PU is also known as wet PU. There are also variations of PU resins with higher solid content and less solvent percentage, known as high-solid PU.

Benefits of PU Synthetic Leather

- Versatile and cruelty-free alternative to genuine leather.

- Widely used in fashion, upholstery, automotive interiors, and accessories.

PU synthetic leather offers a visually appealing and durable option for those looking for a leather-like material without the use of animal products.

Common terms used in the production of PU synthetic leather.

- RP (Release paper): also known as casting paper, is used to cast certain patterns onto a coated resin surface. The paper is embossed with a pattern, and when liquid resin is coated over the embossed paper and dried into a solid layer, the pattern becomes molded onto the resin surface. This is one of the methods used to create surface patterns in PU leather.

Check out our previous articles Release paper Introduction, production and type - DMF: Dimethylformamide (DMF) is a toxic organic solvent commonly used in PU resin production. It can be harmful to human health and is considered a volatile organic compound (VOC) that contributes to air pollution.

- DMF-free PU leather: refers to synthetic leather (faux leather / artificial leather) made of polyurethane that does not contain dimethylformamide (DMF) solvent. The PU resins used in DMF-free PU leather production are formulated without the use of DMF, and the manufacturing process of the synthetic leather does not involve the use of DMF solvent. This makes DMF-free PU leather a safer and more environmentally friendly option compared to PU leather produced with DMF.

- Water-based PU leather: produced using a liquid-state DMF-free water-based polyurethane resin. The production process involves coating the resin on a release paper to create a solid PU skin layer with a pattern. Then, a batch of water-based PU resin is mixed with air to create a foam layer, which is coated onto the back of the skin. A backing material is laminated onto the foam layer to create the skin + foam + backing structure. This process does not involve the use of DMF or water tanks, making it a more environmentally friendly option compared to solvent-based PU production

- BC (Backing Clothes) also known as Backer or Backing: is a term commonly used in the production of PU synthetic leather. It refers to the textile material used as the bottommost layer of the PU leather, providing support and stability to the material.

Application

PU synthetic leather finds a wide range of applications in various industries. Here are some common uses:

- Fashion and Apparel: PU synthetic leather is often used as a substitute for genuine leather in the fashion and apparel industry. It is used to make shoes, handbags, wallets, belts, and other accessories.

- Furniture and Upholstery: PU synthetic leather is widely used in the furniture industry to upholster chairs, sofas, and other seating arrangements. It provides a cost-effective and durable alternative to genuine leather.

- Automotive Interiors: Many car manufacturers use PU synthetic leather for the interiors of their vehicles. It is used to cover seats, door panels, and dashboard surfaces. PU synthetic leather offers a similar look and feel to genuine leather at a lower cost.

- Electronics and Gadgets: PU synthetic leather is also used in the production of electronic devices and gadgets. It is commonly used for phone cases, tablet covers, and laptop sleeves.

- Bookbinding: PU synthetic leather is used in the production of book covers and bindings. It provides a durable and attractive alternative to traditional cloth or paper covers.

- Sports and Fitness Equipment: PU synthetic leather is utilized in the production of sports and fitness equipment such as gloves, balls, and protective gear. It offers the necessary flexibility and durability required for these applications.

These are just a few examples of the wide-ranging applications of PU synthetic leather. Its versatility, affordability, and durability make it a popular choice in many industries.

Leave a Reply