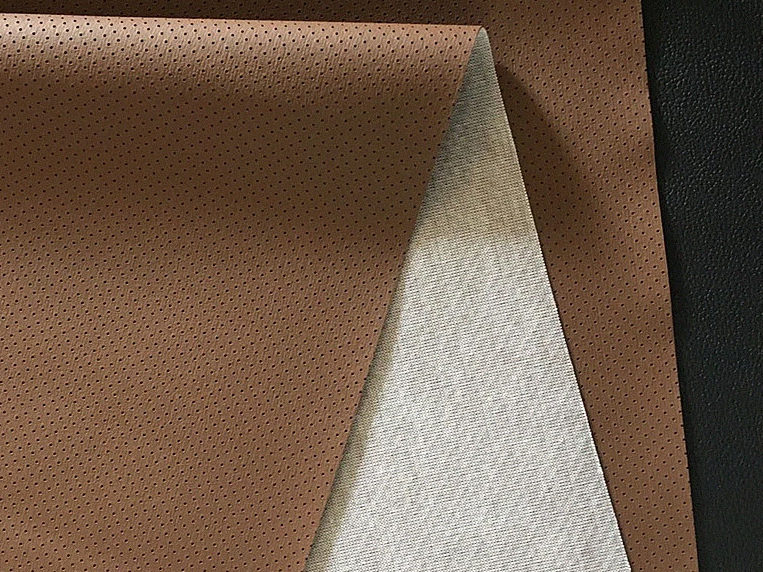

Artificial leather, also known as faux leather, is a popular fabric material that is commonly used in the fashion and furniture industries. To achieve the desired texture and appearance, artificial leather requires a backing fabric. This backing fabric provides support, stability, and shape to the artificial leather, ensuring that it maintains its form and structure.

There are two main types of backing fabrics that are commonly used for artificial leather: knit and woven fabric. Each of these fabrics has unique properties and characteristics that make it suitable for specific applications. In this article, we will explore the differences between knit and woven backing fabrics for artificial leather and their respective benefits.

1. Knitted fabric

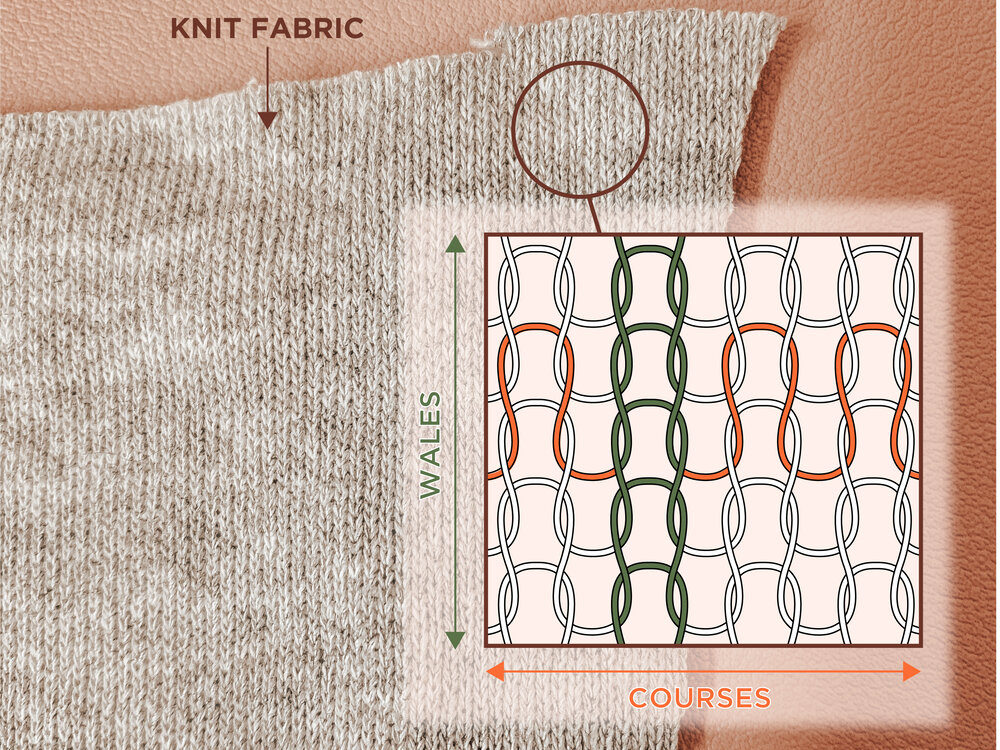

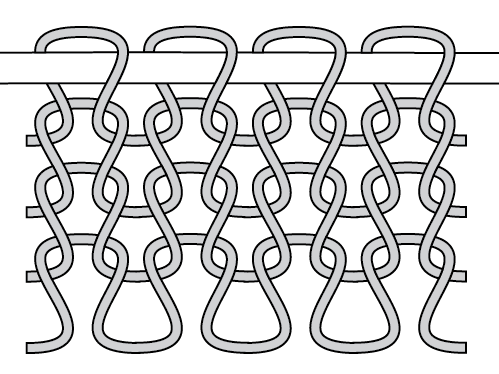

Knitted fabric is a fabric made up of loops of yarn that are interwoven according to a certain structure. Loops are interconnected in vertical and horizontal directions. New loops will be inserted through the old loops and so on to form the fabric.

Knitted fabrics have a loop structure, including:

– Horizontal rows: are called courses. On each row of loops, the loops can be vertical or left oblique, or right oblique.

– Vertical columns: are called wales. On each column of loops, the loops can lie vertically or obliquely to form symmetrical zigzag lines.

Types of knitted fabric

There are two types of knitted fabric, weft-knitted fabric, and wrap-knitted fabric

In weft-knitted fabric, the loop (Wales) will be perpendicular to the loop (Course) of the yarn. Weft knitted fabric has been woven from many yarns corresponding to the number of needles, all of which participate in looping and creating the fabric. It has some basic weaves, such as Single jersey, Rib, Interlock…

In warp-knitted fabric, the vertical loops (Wales) along with the loops of yarn almost parallel. In theory, the fabric could be produced with a single yarn. And it’s made by quite simply weaving each row one after the other. In contrast to weft knits, in warp-knitted fabric, one thread is required for each column. Currently, there are 3 types of warp knitting fabrics: Tricot, Milan, Raschel.

2. Woven fabric

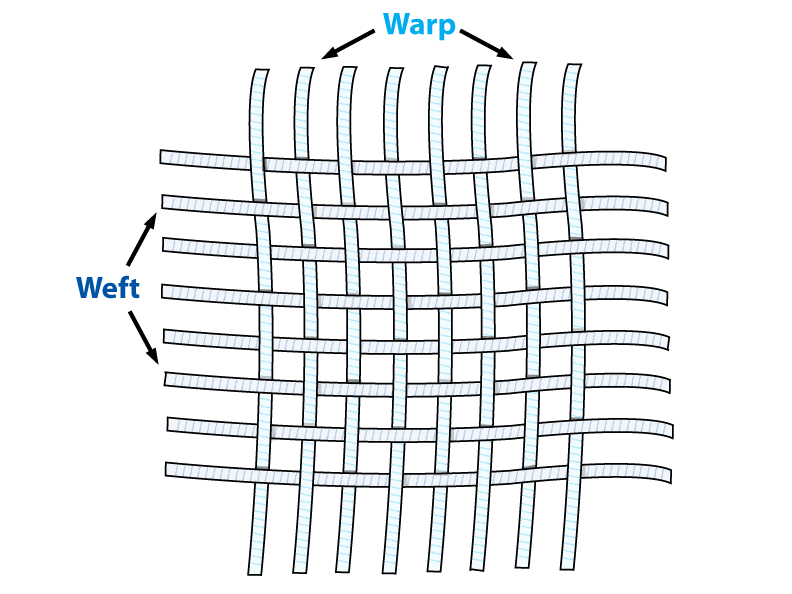

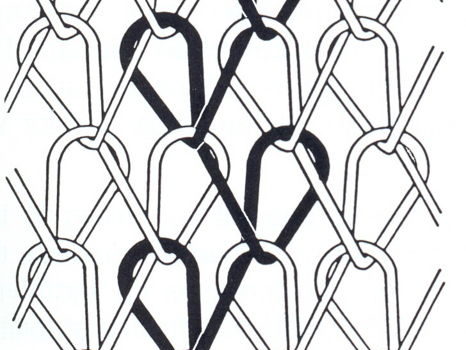

Woven fabric is an alternating combination of warp yarn and weft yarn woven at right angles to each other. The warp yarn is the thread that runs through the length of the fabric, and the weft yarn is the thread that runs horizontally. Depending on different weaves, people will combine the warp and weft in different ways. From there, many different types of woven fabrics are created.

3. Choose the backing fabric for manufacturing artificial leather

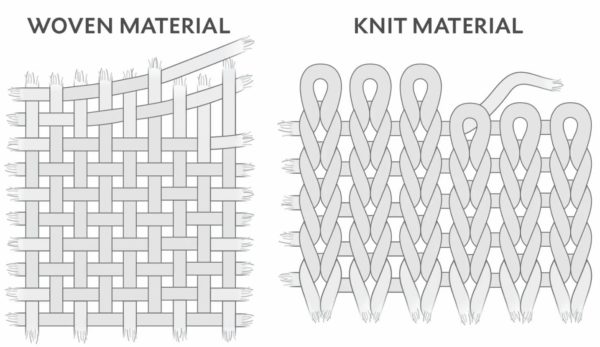

The difference between woven & knitted fabrics is mainly in the weave, with the woven materials having a close weave (less flexible) and the knitted fabrics having more open weave and very flexible.

In artificial leather, although the type of coating used plays a major role in the final quality product, final quality also depends heavily on the fabrics on which coatings are built. According to international standards, some of the basic specifications required when manufacturing artificial leather are – fabric weight, aging, thickness, yarn count, shrinkage factor, tear strength, and others, while end-user needs properties such as permeability, water absorption factor, flexibility, thermal resistance, and others will be of value. The textile backing fabrics are mainly responsible for determining the stretch and weight per unit area and strength of these synthetic leathers.

Synthetic leathers are used to have the overall coated thicknesses may vary between 0.4 – 1.2mm. Whatever type of yarn or knit is used, one must remember that during the coating process, the temperature for PVC is around 180-200°C, while for PU, it is much less probably in the range of 60-70°C. If different layers of polymeric coatings are used, the temperature structures will be different. Since heat is the final curing medium for all polymeric coatings, it is to be expected that the strength of the backing fabrics used will be affected and thus the overall strength of the final product. Therefore, when selecting backing fabric, a manufacturer of synthetic leather must select a suitable one.

Conclusion

In conclusion, both knitted and woven fabrics can be used as backing fabrics for artificial leather, depending on the intended application. Knit fabrics are more flexible and stretchy, making them ideal for applications that require a high degree of flexibility, such as clothing and accessories. Woven fabrics, on the other hand, offer greater stability and structure, making them better suited for furniture and upholstery applications. Ultimately, the choice between these two types of backing fabrics will depend on the specific needs of the application, and manufacturers should carefully consider the desired texture, appearance, and performance of the artificial leather before selecting a backing fabric.

Leave a Reply